Project Introduction

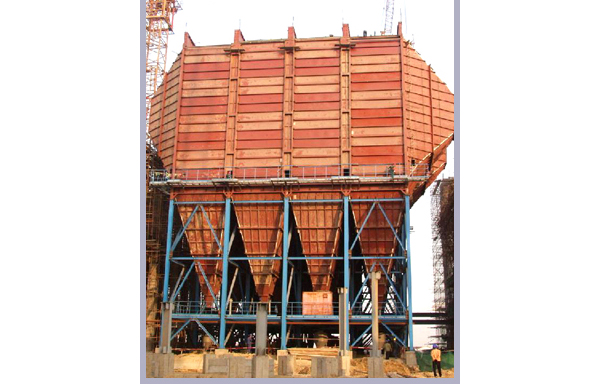

[Steel Structure Grid Project of Electrostatic Precipitator in Yunhe Power Plant]

运河电厂电除尘器钢结构网架工程,电除尘器钢结构网架工程Power plant grid

Electric dust removal is a kind of gas dust removal method. The dust-containing gas is electrically separated when passing through a high-voltage electrostatic field, and the dust particles combine with negative ions to be negatively charged, and then discharge toward the anode surface and deposit. Used in metallurgy, chemical and other industries to purify gas or recover useful dust particles. A dust collection method that uses an electrostatic field to ionize gas so that dust particles are charged and adsorbed on the electrode. In a strong electric field, air molecules are ionized into positive ions and electrons. The electrons encounter dust particles in the process of running toward the positive electrode, causing the dust particles to be negatively charged and adsorbed to the positive electrode to be collected. It is often used in factories and power stations that use coal as fuel to collect coal ash and dust in flue gas. Used in metallurgy to collect oxides of tin, zinc, lead, and aluminum.

Electrostatic precipitator is a necessary accessory equipment for thermal power plants. Its function is to remove particulate smoke and dust in the flue gas emitted by burning stoves or oil-fired boilers, thereby greatly reducing the amount of smoke and dust discharged into the atmosphere, which is to improve environmental pollution , An important environmental protection equipment to improve air quality. Its working principle is that when the flue gas passes through the flue in front of the main structure of the electrostatic precipitator, the flue gas is positively charged, and then the flue gas enters the electrostatic precipitator channel with multi-layer cathode plates. Due to the mutual adsorption of the positively charged soot and the cathode plate, the particulate soot in the flue gas is adsorbed on the cathode, and the cathode plate is regularly hit, so that the dust with a certain thickness falls on the electrostatic precipitator under the dual effects of its own weight and vibration. In the ash hopper under the structure, so as to achieve the purpose of removing the smoke and dust in the flue gas.

Because thermal power plants generally have relatively large power units, such as 600,000 kilowatts, which burn coal up to about 180T per hour, the amount of smoke and dust can be imagined. Therefore, the structure of the corresponding electrostatic precipitator is also relatively large. The cross-sectional size of the main structure of the electrostatic precipitator used in general thermal power plants is about 25-40×10-15m. If the height of the ash hopper of 6 meters and the density of the smoke transportation space are added, the height of the entire electrostatic precipitator is 35 meters. Above, for such a huge steel structure, it is not only necessary to consider the static and dynamic analysis under the action of autonomy, smoke load, wind load, and earthquake load. At the same time, the stability of the structure must also be considered.

The main structure of the electrostatic precipitator is a steel structure, all welded by section steel, and the outer surface is covered with skin (thin steel plate) and thermal insulation materials for the convenience of design, manufacture and installation. The structural design adopts a layered form, each piece is composed of several main beams of frame type, and the pieces are connected by large beams. In order to install the skin and the insulation layer, the main beams are welded and the secondary beams are added. For such a large structure, how to connect them according to the physical objects, the workload and the number of units will be very huge. According to the actual design requirements of the project and the main structure design of the electrostatic precipitator, the structure strength, structural stability and the maximum displacement of the main beam of the suspended cathode plate are mainly investigated. For the local area, the fatigue damage of the connection between the cathode plate and the main beam under long-term periodic blows is mainly investigated; the best frequency selection of smoke and dust falling off the cathode plate; the structure surface skin (thin plate) and the main and secondary beams under wind load The best choice of connection and stiffness between them and so on.